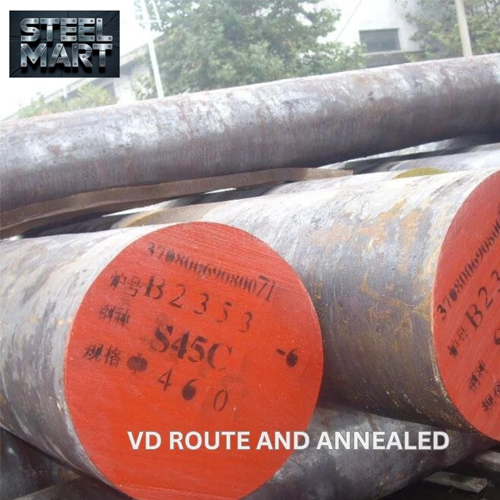

About C45 VD Route And Annealed Heavy Duty Forged Round Bar

C45 steel is a medium carbon steel known for its good tensile strength and machinability. It is often used in applications requiring higher strength and wear resistance than mild steel, such as gears, bolts, and shafts.

Key Features of C45 Steel:

- Composition: C45 steel typically contains 0.42-0.50% carbon, 0.50-0.80% manganese, and small amounts of silicon, sulfur, and phosphorus.

- Mechanical Properties: It offers good tensile strength, typically around 570-700 N/mm, and a yield strength of about 330-460 N/mm1.

- Heat Treatment: C45 can be heat treated to improve its mechanical properties. It is often supplied in the normalized or annealed condition to enhance its machinability and toughness2.

VD Route:The Vacuum Degassing (VD) route is a steelmaking process that removes dissolved gases like hydrogen and nitrogen from the molten steel. This process improves the steels quality by reducing the risk of defects and enhancing its mechanical properties1.

Annealed Round Bars:Annealed round bars of C45 steel are heat-treated to relieve internal stresses and improve machinability. The annealing process involves heating the steel to a specific temperature and then slowly cooling it. This results in a softer and more ductile material, making it easier to machine and form2.

Applications:C45 steel round bars are widely used in the manufacturing of:

- Gears

- Bolts

- Shafts

- Axles

- Studs

- General engineering components

Exceptional Machinability & StrengthC45 VD Route and Annealed Heavy Duty Forged Round Bars are designed for superior machinability and mechanical performance. With a yield strength around 330 MPa and excellent toughness, these bars are ideal for industries seeking durability and efficient processing. The annealed condition further enhances their suitability for precision engineering tasks.

Precision Forging & Processing ServicesEach round bar is produced using vacuum degassing (VD) route forging, which minimizes impurities and ensures metal homogeneity. Companies benefit from our comprehensive processing services, including forging and high-precision machining, delivering products with close cutting tolerances in line with modern industrial requirements.

Reliable Supply Across IndiaAs a reputable dealer, distributor, and manufacturer in India, we ensure prompt delivery and consistent stock availability for varying industry needs. Whether you are a trader or a wholesaler, you can count on us for quality products and customizable minimum order quantities.

FAQ's of C45 VD Route And Annealed Heavy Duty Forged Round Bar:

Q: How is the C45 VD Route and Annealed Heavy Duty Forged Round Bar manufactured?

A: These round bars are manufactured using the vacuum degassing (VD) route forging process, which removes impurities and ensures a uniform, high-quality material structure. The bars are then annealed to deliver enhanced machinability and toughness.

Q: What applications are best suited for this round bar?

A: Thanks to its excellent machinability, high toughness, and moderate weldability, this round bar is ideal for components subjected to high fatigue and impact, such as mechanical shafts, gears, and automotive parts.

Q: When can I expect delivery if I place an order?

A: We maintain ready stock for prompt delivery across India. Orders are processed based on your required quantity, ensuring a quick turnaround for both standard and customized requests.

Q: Where do you supply your round bars?

A: We are a comprehensive supplier, dealer, exporter, importer, and distributor, serving customers throughout India and internationally as requested.

Q: What benefits does the annealed condition offer for this product?

A: The annealed delivery condition enhances machinability and workability, allowing for easier shaping, cutting, and further processing. It also reduces internal stresses in the metal, increasing its suitability for precision engineering.

Q: How does the close cutting tolerance benefit my application?

A: Close cutting tolerances ensure that each bar meets strict dimensional requirements, facilitating accurate assembly and reducing the need for further modification, which can save both time and material costs.

Q: Is there a minimum order quantity for C45 VD round bars?

A: Yes, the minimum order quantity (MOQ) is tailored to your specific needs, allowing flexibility for both bulk and smaller quantities to accommodate various project sizes.