About P20 Machined And Ground Plates

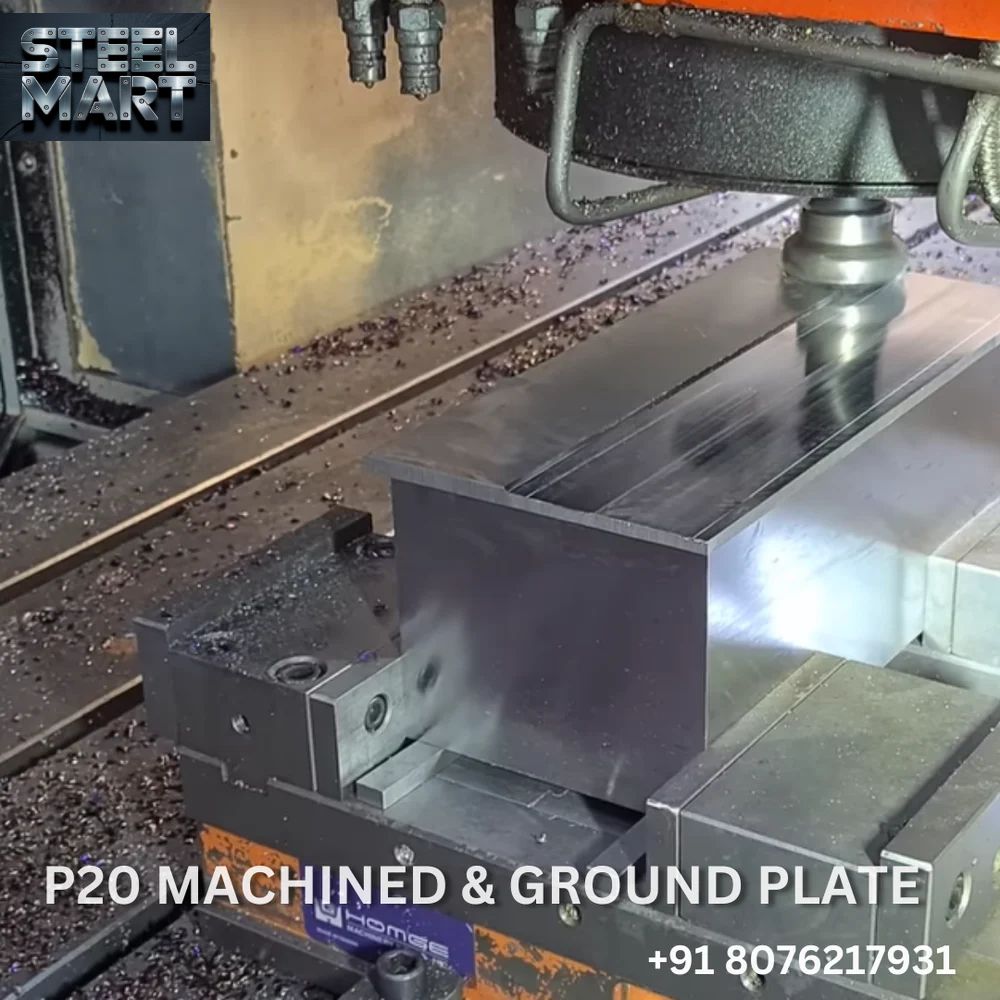

A machined and Ground Finish plate is a type of metal plate that has undergone precise machining and grinding processes to achieve specific dimensions, flatness, and surface finish. Heres a breakdown of the key aspects:

Machined Plate

Applications: Commonly used in manufacturing, construction, and engineering for components that require precise fitting and alignment.

Ground Finish Plate

Grinding: This process involves using abrasive wheels to remove material and achieve a high degree of flatness and a smooth surface finish.

Surface Finish: Ground plates have a very smooth and even surface, which is crucial for applications requiring minimal friction and high precision.

Applications: Often used in toolmaking, machine bases, and fixtures where a high degree of accuracy and surface quality is essential.

Combined Machined and Ground Finish Plate

Enhanced Precision: Combining machining and grinding processes results in plates that meet stringent specifications for both dimensions and surface quality.

Versatility: These plates are versatile and can be used in various industries, including aerospace, automotive, and heavy machinery

Unmatched Precision & ConsistencyThe P20 Machined and Ground Plates feature a tight flatness tolerance of 0.02 mm with meticulously deburred and sharp edges, ensuring consistent, reliable performance in demanding industrial scenarios. Their fine surface roughness and dimensional integrity make them perfect for tooling and mold base production.

Superior Material PropertiesBeing prehardened and magnetic, these plates offer robustness and versatility in a range of applications. Their density of ~7.8 g/cm3 reinforces durability, while excellent machinability streamlines fabrication and modifications. Good weldability further amplifies their utility in various manufacturing processes.

Widespread Availability and ServiceP20 plates are supplied, traded, and exported throughout India by a network of dealers, wholesalers, manufacturers, and service providers. Whether you need bulk quantities or customised solutions, you can access prompt support and reliable delivery from numerous industry experts across the country.

FAQ's of P20 Machined And Ground Plates:

Q: How are P20 Machined and Ground Plates typically processed and finished?

A: P20 plates undergo precision machining and grinding to achieve the specified flatness tolerance and fine surface finish. Edges are sharpened and carefully deburred for safety and accuracy, and the plates are delivered in a prehardened condition for immediate use.

Q: What applications are best suited for P20 Machined and Ground Plates?

A: These plates excel in mold-making, tool bases, and components requiring high dimensional stability, excellent machinability, and good weldability due to their flatness, hardness, and magnetic properties.

Q: When is it beneficial to use prehardened P20 plates instead of annealed varieties?

A: Using prehardened P20 plates saves time and costs by eliminating the need for separate hardening processes after machining, making them ideal for time-sensitive and high-precision industrial applications.

Q: Where can I purchase P20 Machined and Ground Plates in India?

A: You can acquire P20 plates through an extensive network of dealers, distributors, exporters, importers, manufacturers, retailers, suppliers, and wholesalers across India. Many service providers also offer customized solutions and prompt delivery.

Q: What are the primary benefits of using P20 Machined and Ground Plates for my projects?

A: These plates offer dimensional accuracy, excellent machinability, good weldability, and fine surface finish, which contribute to increased productivity, reduced machining time, and enhanced quality in end-use applications.

Q: How does the magnetic property of P20 plates influence their usage?

A: The magnetic nature of P20 plates is advantageous in applications involving electromagnetic fixtures, magnetic clamping, or assembly processes where magnetic alignment is beneficial.