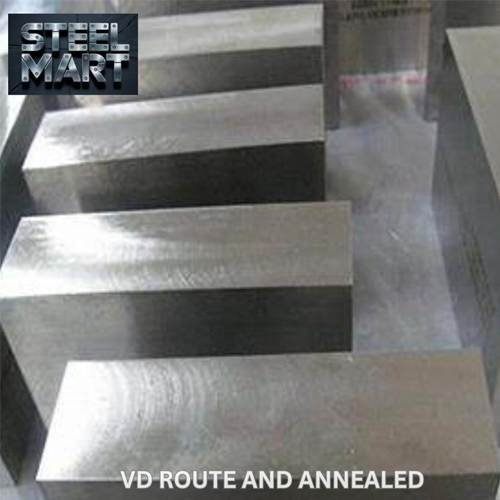

About En41b VD Route And Annealed Forged Block

EN41B VD Route and Annealed Forged Block

Our EN41B VD Route and Annealed Forged Blocks are designed to meet the highest standards of quality and performance, making them ideal for a wide range of industrial applications.

Material Specifications:

- Grade: EN41B (also known as 41CrAlMo7 or 1.8509)

- Composition: This high-quality nitriding steel is known for its excellent hardness, wear resistance, and toughness1.

Processing Details:

- VD Route: Processed via Vacuum Degassing to ensure superior cleanliness and reduced impurities.

- Annealing: The blocks are annealed to enhance machinability and reduce internal stresses, making them ideal for further processing and fabrication2.

Key Features:

- High Hardness: Suitable for applications requiring high wear resistance and durability.

- Excellent Machinability: The annealed condition improves ease of machining.

- Abrasion Resistance: Ideal for components subjected to high wear and tear1.

Applications:

- Automotive: Perfect for gears, shafts, and other high-stress components.

- Machinery: Suitable for various machine parts requiring high tensile strength.

- Tooling: Ideal for manufacturing press tools and other wear-resistant machine components2.

- Aerospace: Used in components that require high strength and resistance to wear2.

Why Choose Our EN41B Blocks?

- Quality Assurance: Adherence to strict quality control measures to meet international standards.

- Customization: Available in customized sizes and shapes to meet specific requirements.

- Reliable Supply: Efficient supply chain ensures timely delivery.

For more details or to place an order, please contact us. We are dedicated to providing top-quality EN41B VD Route and Annealed Forged Blocks to meet your needs.

Vacuum Degassed for Premium PurityThrough VD refining, the En41b block achieves ultra-low impurities, resulting in cleaner steel with improved properties. The annealed and forged process further enhances its workability and overall mechanical strength, making it the preferred choice for critical OEM and industrial applications.

Homogeneous Microstructure and Precision MachiningA uniform grain structure ensures consistent mechanical behavior and superior machinability. Precision cutting during production guarantees dimensional accuracy, reducing waste and optimizing both small and large-scale fabrication.

FAQ's of En41b VD Route And Annealed Forged Block:

Q: How is the En41b Annealed Forged Block processed to ensure high quality?

A: The En41b block is refined using a vacuum degassing (VD) process, which removes impurities and gases. It is then annealed and forged, resulting in a homogeneous grain structure, premium machinability, and superior toughness. Every block is supplied with a Mill Test Certificate for quality assurance.

Q: What benefits does the homogeneous grain structure provide?

A: A homogeneous grain structure offers consistent mechanical properties throughout the block, enhancing toughness, impact strength, and reducing the risk of internal defects. This makes the block suitable for highly demanding engineering and OEM applications.

Q: When is the En41b Block typically used in industrial settings?

A: The En41b VD Route And Annealed Forged Block is used when high machinability, superior impact strength, and precise dimensional accuracy are required-such as in OEM parts production, heavy engineering, and high-stress industrial environments.

Q: Where can I source En41b Forged Blocks in India?

A: You can source En41b Forged Blocks from numerous channels such as dealers, distributors, exporters, importers, manufacturers, service providers, suppliers, traders, and wholesalers located across India. Ready stock is often available for immediate fulfillment.

Q: What is the delivery condition of these forged blocks?

A: The blocks are supplied in an annealed and forged condition, ensuring optimal machinability and performance. Precision cutting ensures they meet exacting industrial requirements.

Q: How does the vacuum degassed (VD) process improve product quality?

A: The VD process eliminates dissolved gases and impurities from the steel, leading to higher purity, enhanced mechanical properties, reduced inclusion content, and greater consistency-critical for high-performance applications.