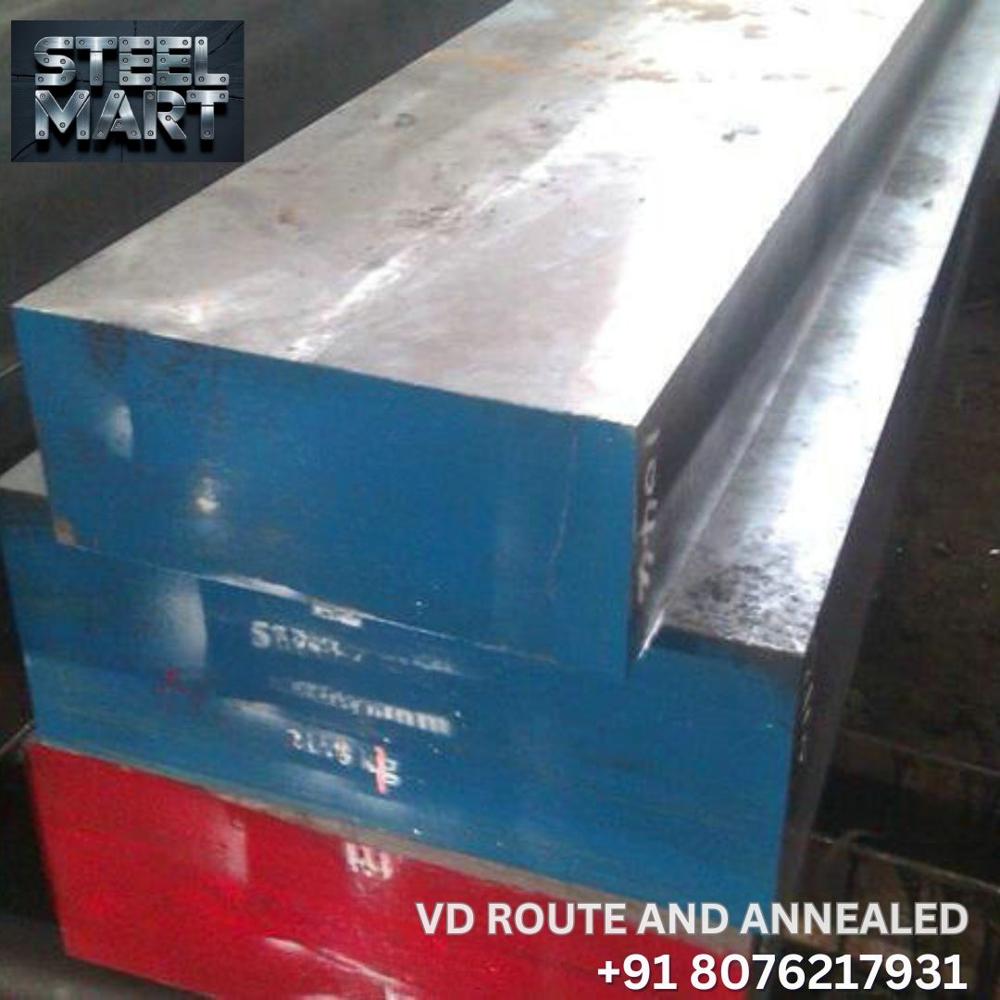

About C55 VD Route And Annealed Forged Block

C55 steel is a medium carbon steel known for its good tensile strength and wear resistance. It is often used in applications requiring higher strength and durability, such as gears, shafts, and bolts.

Key Features of C55 Steel:

- Composition: C55 steel typically contains 0.50-0.60% carbon, 0.50-0.80% manganese, and small amounts of silicon, sulfur, and phosphorus1.

- Mechanical Properties: It offers good tensile strength, typically around 700-850 N/mm, and a yield strength of about 450-600 N/mm2.

- Heat Treatment: C55 can be heat treated to improve its mechanical properties. It is often supplied in the normalized or annealed condition to enhance its machinability and toughness1.

VD Route:The Vacuum Degassing (VD) route is a steelmaking process that removes dissolved gases like hydrogen and nitrogen from the molten steel. This process improves the steels quality by reducing the risk of defects and enhancing its mechanical properties3.

Annealed Round Bars:Annealed round bars of C55 steel are heat-treated to relieve internal stresses and improve machinability. The annealing process involves heating the steel to a specific temperature and then slowly cooling it. This results in a softer and more ductile material, making it easier to machine and form1.

Applications:C55 steel round bars are widely used in the manufacturing of:

- Gears

- Shafts

- Bolts

- Axles

- Studs

- General engineering components

Advanced Forging TechnologyOur C55 Forged Block is produced via the VD (Vacuum Degassing) route, ensuring minimal impurities and superior metallurgical properties. This advanced process contributes significantly to the block's reliability, mechanical consistency, and overall performance, making it suitable for demanding requirements across industries.

Enhanced Properties with Annealed FinishThe annealing thermal treatment applied to the forged block ensures a uniform structure, improved toughness, and optimum machinability. The delivery in an annealed condition makes it ready for further processing, offering consistency in quality and performance for both large-scale and precision applications.

FAQ's of C55 VD Route And Annealed Forged Block:

Q: How is the C55 VD Route and Annealed Forged Block manufactured?

A: The block is produced using the VD (Vacuum Degassing) forging method followed by a precise annealing thermal treatment. This combination minimizes impurities, enhances metallurgical integrity, and achieves optimal mechanical and machining properties.

Q: What are the primary benefits of using the C55 Forged Block with VD Route and annealed condition?

A: This forged block offers high machinability for easier processing, good impact strength for durability, and reliable performance due to its controlled forging and annealing procedures. The annealed delivery condition also ensures the block is suitable for immediate further manufacturing steps.

Q: When should the C55 annealed forged block be selected for applications?

A: It is ideal for situations requiring a blend of high toughness, good impact absorption, and excellent machinability-commonly found in automotive components, engineering equipment, and heavy machinery manufacture.

Q: Where can customers and businesses in India procure the C55 VD Route and Annealed Forged Block?

A: Customers can source this forged block through an extensive network of dealers, distributors, manufacturers, retailers, exporters, importers, service providers, suppliers, traders, and wholesalers across India.

Q: What processes are used to ensure the machinability and toughness of this forged block?

A: The block undergoes vacuum degassing for purity, forging for grain uniformity, and thermal annealing for structural refinement. These stages together produce a tough yet highly machinable material.

Q: How is the C55 Forged Block delivered to end-users?

A: It is provided in an annealed condition, making it ready for additional machining and fabrication processes as per user requirements, thereby saving time in production lines.