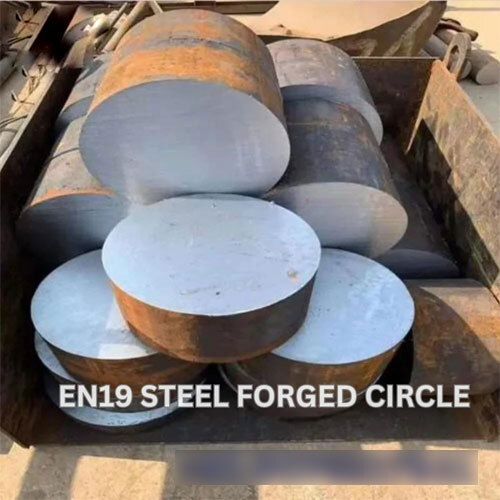

About En19 Alloy Steel Forged Circle

Steel World is stockiest, supplier, dealer and manufacturer of the En19 Steel Forged Circle.EN19 Steel, also known as 42CrMo4 or SAE 4140, is a versatile alloy steel with excellent mechanical properties. Lets dive into the details: Composition: Carbon: 0.35 0.50%Manganese: 0.90 1.50%Chromium: 0.80 1.20%Molybdenum: 0.20 0.40%Silicon: 0.10 0.35%Sulfur (max): 0.035%Phosphorus (max): 0.035%Properties:Hardness: EN19 steel can be heat-treated to achieve high hardness (typically around 223-331 Brinell).Tensile Strength: It exhibits impressive tensile strength (775-1000 N/mm).Yield Strength: EN19 has a yield strength of 555-755 N/mm.Elongation: Approximately 12-13%.Impact Toughness (Izod KCV): Ranges from 22 to 50 J. Applications: Forged Components: EN19 steel is commonly used for forged flat bars, such as crankshafts and connecting rods. Automotive Gears and Parts: Suitable for high-loading applications like engine gearboxes. Oil & Gas Industry: EN19 has gained popularity in this sector due to its strength. Remember that EN19 steel is often heat-treated to enhance its properties.EN19 Steel, also known as 42CrMo4 or SAE 4140, is a versatile alloy steel with excellent mechanical properties. Lets dive into the details: Composition: Carbon: 0.35 0.50%Manganese: 0.90 1.50%Chromium: 0.80 1.20%Molybdenum: 0.20 0.40%Silicon: 0.10 0.35%Sulfur (max): 0.035%Phosphorus (max): 0.035%Properties:Hardness: EN19 steel can be heat-treated to achieve high hardness (typically around 223-331 Brinell).Tensile Strength: It exhibits impressive tensile strength (775-1000 N/mm).Yield Strength: EN19 has a yield strength of 555-755 N/mm.Elongation: Approximately 12-13%.Impact Toughness (Izod KCV): Ranges from 22 to 50 J. Applications: Forged Components: EN19 steel is commonly used for forged flat bars, such as crankshafts and connecting rods. Automotive Gears and Parts: Suitable for high-loading applications like engine gearboxes. Oil & Gas Industry: EN19 has gained popularity in this sector due to its strength. Remember that EN19 steel is often heat-treated to enhance its properties.Exceptional Mechanical PerformanceEN19 Alloy Steel Forged Circles deliver high fatigue and impact strength, ensuring resilience under heavy-duty use. Their tempered or quenched finish boosts longevity, making them ideal for structural, automotive, and general engineering projects where reliability is key.

Versatile Machining and CustomizationThanks to their good machinability rating, EN19 circles support CNC-based cutting for precision results. Customization is available to match exact project needs, complemented by smooth edge profiles and tight tolerances that meet industry demands.

Corrosion Protection and Ready SupplyPolished and oiled surfaces provide reliable rust prevention, preserving material quality during storage and application. Ready stock throughout India-offered by a diverse network of distributors, manufacturers, and wholesalers-ensures quick delivery and competitive sourcing.

FAQ's of En19 Alloy Steel Forged Circle:

Q: How can EN19 Alloy Steel Forged Circles benefit my engineering projects?

A: EN19 Forged Circles offer high impact and fatigue strength, making them ideal for applications requiring toughness and reliability. Their good machinability and tight tolerances allow for precise, custom-engineered components, while rust-preventive finishes extend service life.

Q: What machining processes are compatible with EN19 Alloy Steel Circles?

A: These circles are suitable for CNC-supported cutting processes, providing clean, smooth edges. Their moderate weldability and high polishability further support advanced fabrication and finishing needs.

Q: When is the delivery of EN19 Alloy Steel Forged Circles possible?

A: Most suppliers and distributors maintain ready stock, enabling prompt delivery throughout India. Delivery timelines may vary for custom orders based on specifications and quantity.

Q: Where can I source EN19 Alloy Steel Forged Circles in India?

A: You can obtain these circles from a wide network including dealers, direct manufacturers, exporters, wholesalers, and service providers across India. Many suppliers offer nationwide shipping.

Q: What is the process for customizing EN19 Alloy Steel Forged Circles?

A: Customization involves precise CNC machining based on your design requirements, achieving specified dimensions, tolerances, and surface finish. The material can be tempered or quenched as needed, and customized minimum order quantities are negotiable.

Q: How does the oiled surface of EN19 Alloy Steel Circles prevent rust?

A: The application of oil creates a protective barrier on the steel's surface, significantly reducing the risk of moisture-induced corrosion during storage, transport, and early use in applications.