About En19 VD Route And Annealed Heavy Duty Forged Block

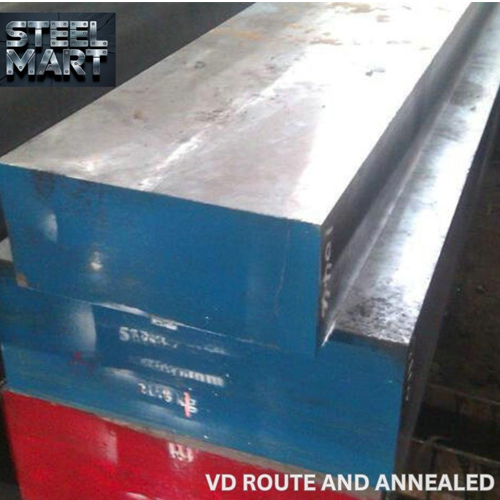

EN19 VD Route and Annealed Heavy Duty Forged Block

Our EN19 VD Route and Annealed Heavy Duty Forged Blocks are engineered to deliver exceptional performance in the most demanding applications. Heres what sets them apart:

Material Specifications:

- Grade: EN19 (also known as 708M40 or AISI 4140)

- Composition: This high-quality alloy steel is renowned for its excellent combination of toughness, strength, and wear resistance1.

Processing Details:

- VD Route: Processed via Vacuum Degassing to ensure superior cleanliness and reduced impurities.

- Annealing: The blocks are annealed to enhance machinability and reduce internal stresses, making them ideal for further processing and fabrication2.

Key Features:

- High Tensile Strength: Suitable for applications requiring high strength and durability.

- Excellent Machinability: The annealed condition improves ease of machining.

- Wear Resistance: Ideal for components subjected to high wear and tear1.

- Heavy Duty Performance: Designed to withstand heavy loads and harsh operating conditions, ensuring reliable performance in critical applications2.

Applications:

- Automotive: Perfect for gears, shafts, and other high-stress components.

- Machinery: Suitable for various machine parts requiring high tensile strength.

- Oil & Gas: Ideal for components that need to withstand harsh environments and high pressures2.

- Construction: Used in the fabrication of structural components, such as bolts, nuts, and shafts, contributing to the durability and integrity of infrastructure projects2.

Why Choose Our EN19 Heavy Duty Blocks?

- Quality Assurance: Adherence to strict quality control measures to meet international standards.

- Customization: Available in customized sizes and shapes to meet specific requirements.

- Reliable Supply: Efficient supply chain ensures timely delivery.

For more details or to place an order, please contact us. We are dedicated to providing top-quality EN19 VD Route and Annealed Heavy Duty Forged Blocks to meet your needs.

Engineered for PerformanceEach En19 VD Route Forged Block delivers high impact strength, outstanding machinability, and superior workability. Manufactured via Vacuum Degassed forging and then precisely annealed, these blocks offer excellent structural integrity and low porosity for high-demand engineering applications. Sharp machined edges add to machining efficiency, and the product is offered in various sizes to match client specifications.

Customized to Your RequirementsWith the capacity for customization, these blocks meet the unique needs of diverse industrial sectors across India. Bulk orders, varied dimensions, and tailored mechanical properties ensure that every customer receives components that optimize performance and compatibility for their specific projects.

FAQ's of En19 VD Route And Annealed Heavy Duty Forged Block:

Q: How are En19 VD Route and Annealed Heavy Duty Forged Blocks manufactured?

A: These blocks are produced through a Vacuum Degassed (VD) forging route, followed by heat treatment via annealing. This process enhances material purity, reduces porosity, and increases impact strength, ensuring robust and reliable forged components.

Q: What applications are suitable for these forged blocks?

A: Due to their high impact strength, good machinability, and excellent workability, these blocks are ideal for heavy machinery, automotive components, construction equipment, and engineering projects that require durable and precise materials.

Q: When should I opt for annealed forged blocks with machined sharp edges?

A: Choose annealed forged blocks with machined sharp edges when your application demands precise dimensions, easy machining and assembly, and high mechanical strength, such as in molds, dies, and high-load mechanical assemblies.

Q: Where can I source these products in India?

A: En19 VD Route and Annealed Forged Blocks are available through multiple channels across India, including dealers, distributors, exporters, importers, manufacturers, suppliers, and wholesalers. Leading industry service providers and retailers can facilitate purchase and delivery.

Q: What are the key benefits of low sulphur content in these forged blocks?

A: Low sulphur content minimizes the risk of non-metallic inclusions and enhances the steel's toughness and fatigue resistance, resulting in longer service life and greater reliability for heavy-duty applications.

Q: How does the low porosity and high bulk density benefit usage?

A: Low porosity ensures better structural integrity by reducing the risk of internal voids, while high bulk density means more material strength and stability. These advantages lead to superior performance under stress and heavy loads.