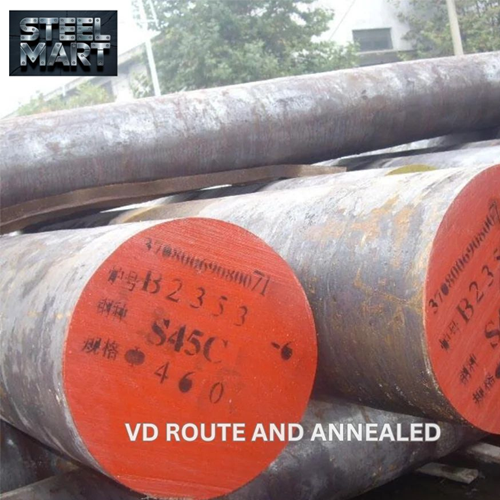

About EN24 VD Route And Annealed Rolled Round Bar

EN24 steel, also known as 817M40 or AISI 4340, is a high-quality alloy steel known for its excellent tensile strength, ductility, and wear resistance. It is widely used in applications requiring high loading and impact resistance, such as gears, shafts, and spindles.

Key Features of EN24 Steel:

- Composition: EN24 steel typically contains 0.35-0.45% carbon, 0.50-0.80% manganese, 1.30-1.80% nickel, 0.90-1.40% chromium, 0.20-0.35% molybdenum, and small amounts of silicon, sulfur, and phosphorus1.

- Mechanical Properties: It offers good tensile strength, typically around 850-1000 N/mm, and a yield strength of about 650-850 N/mm1.

- Heat Treatment: EN24 can be heat treated to improve its mechanical properties. It is often supplied in the normalized or annealed condition to enhance its machinability and toughness2.

VD Route:The Vacuum Degassing (VD) route is a steelmaking process that removes dissolved gases like hydrogen and nitrogen from the molten steel. This process improves the steels quality by reducing the risk of defects and enhancing its mechanical properties1.

Annealed Round Bars:Annealed round bars of EN24 steel are heat-treated to relieve internal stresses and improve machinability. The annealing process involves heating the steel to a specific temperature (typically between 680-700C) and then slowly cooling it. This results in a softer and more ductile material, making it easier to machine and form3.

Applications:EN24 steel round bars are widely used in the manufacturing of:

- Gears

- Shafts

- Spindles

- Bolts

- Automotive components

- General engineering components

Superior Engineering PerformanceEN24 VD Route And Annealed Rolled Round Bars offer a perfect combination of strength, machinability, and versatility. With their decarb-free and annealed rolled finish, these bars maintain dimensional accuracy and low distortion even after heat treatment. The high impact strength makes them ideal for heavy-duty applications that require robust performance. Each bar undergoes ultrasonic testing, ensuring internal integrity for safety-critical projects.

Fully Tested and CustomizableEach EN24 VD bar is ultrasonically tested to guarantee quality and defect-free delivery. Polished ends are available for enhanced aesthetics and safety during handling. Flexible order quantities cater to both small and large requirements, supporting a range of industries. The bars carry clear EN24 VD brand markings for authenticity and traceability, giving buyers added confidence.

FAQ's of EN24 VD Route And Annealed Rolled Round Bar:

Q: How is the EN24 VD Route And Annealed Rolled Round Bar processed and what ensures its quality?

A: The bar is manufactured through annealed rolling, followed by ultrasonic testing for internal soundness. It is decarb free, meaning the surface has no decarburization, ensuring consistent strength and quality. Polished ends and the EN24 VD brand mark further guarantee authenticity and safe handling.

Q: What are the main benefits of choosing EN24 VD Round Bars for engineering projects?

A: Key benefits include high machinability, low distortion risk, and high impact strength. Its suitability for heat treatment and decarb-free finish make it reliable for critical applications. The bar is thoroughly tested and can be supplied with customizable ends for diverse needs.

Q: When is it recommended to use the EN24 VD Route Annealed bar?

A: It is best used when projects demand high strength, excellent machinability, and low distortion after heat treatment-such as in automotive parts, machinery components, and high-impact tools.

Q: Where is the EN24 VD Route And Annealed Rolled Round Bar available in India?

A: You can source these bars through a broad network of dealers, distributors, exporters, importers, manufacturers, producers, retailers, service providers, suppliers, traders, and wholesalers throughout India.

Q: What is the process to place an order for EN24 VD Round Bars with flexible quantities?

A: Orders can be placed directly with any authorized distributor, dealer, or manufacturer. Flexible order quantities are supported, accommodating both bulk and smaller-scale requirements according to your project needs.

Q: How do polished ends and ultrasonic testing add value to the EN24 VD bars?

A: Polished ends improve safety and handling, while ultrasonic testing ensures the bar is free from internal flaws, delivering a higher assurance of quality and performance for demanding engineering uses.