About En31 VD Route And Annealed Forged Block

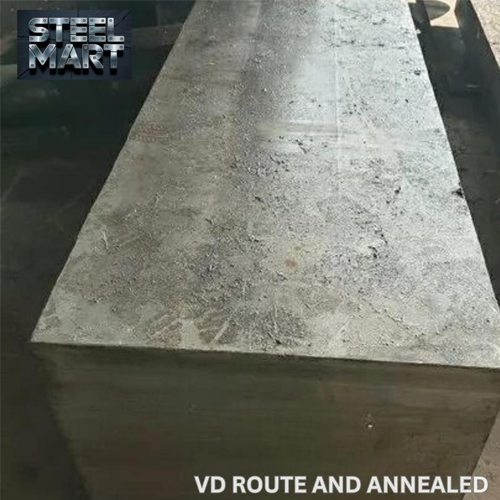

EN31 VD Route and Annealed Forged Block

Our EN31 VD Route and Annealed Forged Blocks are designed to meet the highest standards of quality and performance, making them ideal for a wide range of industrial applications.

Material Specifications:

- Grade: EN31 (also known as SAE 52100)

- Composition: This high-carbon alloy steel is known for its excellent hardness, compressive strength, and abrasion resistance1.

Processing Details:

- VD Route: Processed via Vacuum Degassing to ensure superior cleanliness and reduced impurities.

- Annealing: The blocks are annealed to enhance machinability and reduce internal stresses, making them ideal for further processing and fabrication2.

Key Features:

- High Hardness: Suitable for applications requiring high wear resistance and durability.

- Excellent Machinability: The annealed condition improves ease of machining.

- Abrasion Resistance: Ideal for components subjected to high wear and tear1.

Applications:

- Automotive: Perfect for gears, shafts, and other high-stress components.

- Machinery: Suitable for various machine parts requiring high tensile strength.

- Tooling: Ideal for manufacturing press tools and other wear-resistant machine components2.

Why Choose Our EN31 Blocks?

- Quality Assurance: Adherence to strict quality control measures to meet international standards.

- Customization: Available in customized sizes and shapes to meet specific requirements.

- Reliable Supply: Efficient supply chain ensures timely delivery.

For more details or to place an order, please contact us. We are dedicated to providing top-quality EN31 VD Route and Annealed Forged Blocks to meet your needs.

Superior Mechanical PropertiesEngineered through the VD Route, En31 forged blocks combine high impact strength and excellent machinability post-annealing. Their homogeneous microstructure ensures performance consistency, making them suitable for critical engineering applications.

Versatility and AvailabilityWhether you need custom dimensions or standard blocks, En31 forged blocks are readily available through a wide network of suppliers across India. Prompt supply and squared edges ensure quick integration into your projects.

Optimal Processing and StorageOpen die forging and vacuum degassing impart enhanced durability and reliability. For best results, indoor storage is recommended to maintain the product's superior qualities and magnetic properties.

FAQ's of En31 VD Route And Annealed Forged Block:

Q: How is the En31 VD Route and Annealed Forged Block manufactured?

A: This block is produced through open die forging followed by vacuum degassing (VD Route) and annealing, resulting in improved toughness and a uniform microstructure.

Q: What benefits does vacuum degassed (VD) processing offer?

A: Vacuum degassing removes impurities and gases, enhancing the steel's purity, mechanical strength, and consistency throughout the block.

Q: Where can I source En31 VD Route and Annealed Forged Blocks in India?

A: You can obtain these blocks from a wide array of suppliers including dealers, distributors, manufacturers, exporters, and wholesalers all over India.

Q: When is the product most suitable for machining?

A: The En31 forged block offers optimal machinability after the annealing process, making it ideal for precision engineering operations at that stage.

Q: What are the recommended storage conditions?

A: To preserve its mechanical and magnetic properties, it is best to store the forgings indoors, protecting them from environmental fluctuations.

Q: How can custom size requirements be accommodated?

A: Custom sizes are available upon request, ensuring the block fits specific application needs and project requirements.

Q: What are the primary uses of this forged block?

A: These blocks are widely used in automotive, toolmaking, and engineering industries where high impact toughness and consistent quality are crucial.