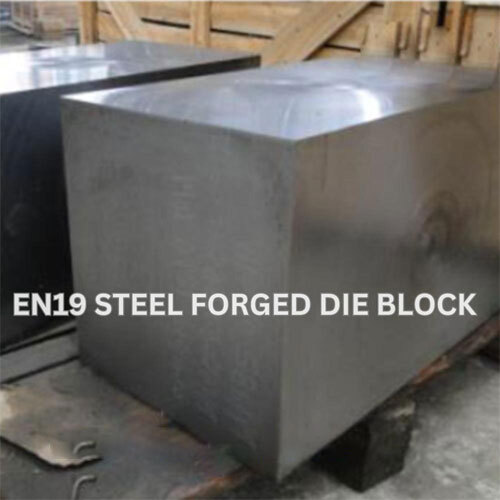

About En19 Alloy Steel Forged Die Block

Steel World is stockiest, supplier, dealer and manufacturer of the En19 Steel Forged Die Block.EN19 Steel, also known as 42CrMo4 or SAE 4140, is a versatile alloy steel with excellent mechanical properties. Lets dive into the details: Composition: Carbon: 0.35 0.50%Manganese: 0.90 1.50%Chromium: 0.80 1.20%Molybdenum: 0.20 0.40%Silicon: 0.10 0.35%Sulfur (max): 0.035%Phosphorus (max): 0.035%Properties:Hardness: EN19 steel can be heat-treated to achieve high hardness (typically around 223-331 Brinell).Tensile Strength: It exhibits impressive tensile strength (775-1000 N/mm).Yield Strength: EN19 has a yield strength of 555-755 N/mm.Elongation: Approximately 12-13%.Impact Toughness (Izod KCV): Ranges from 22 to 50 J. Applications: Forged Components: EN19 steel is commonly used for forged flat bars, such as crankshafts and connecting rods. Automotive Gears and Parts: Suitable for high-loading applications like engine gearboxes. Oil & Gas Industry: EN19 has gained popularity in this sector due to its strength. Remember that EN19 steel is often heat-treated to enhance its properties.Superior Durability and MachinabilityEN19 Alloy Steel Forged Die Blocks stand out for their high impact toughness and good machinability, ensuring efficient processing and long-lasting industrial performance. Their uniform microstructure and stress-relieved state enhance both durability and ease of fabrication, allowing users to achieve precise results with minimal wear on cutting tools.

Versatile Sourcing from Key Indian ProvidersAvailable through reputable dealers, distributors, exporters, manufacturers, traders, and wholesalers across India, EN19 Forged Die Blocks can be easily sourced for various scales of operation. Suppliers accommodate custom cutting needs and respond to minimum order requests, ensuring tailored solutions for engineering and manufacturing sectors.

FAQ's of En19 Alloy Steel Forged Die Block:

Q: How is the EN19 Alloy Steel Forged Die Block typically used in industrial applications?

A: EN19 Alloy Steel Forged Die Blocks are commonly employed in die-making, tooling, and heavy-duty machine parts due to their enhanced impact toughness, fine grain structure, and excellent machinability. Their robustness makes them well-suited for high-stress environments.

Q: What benefits do stress relief and fine grain structure offer in these die blocks?

A: Stress relief mitigates residual internal stresses, reducing the risk of distortion and cracks during machining. A fine grain structure contributes to superior mechanical strength, improved surface finish, and enhanced fatigue resistance.

Q: When should custom cutting be requested for EN19 Die Blocks?

A: Custom cutting should be requested at the time of order placement if specific dimensions or geometries are required. Suppliers across India provide tailored cutting services to ensure the blocks meet precise application needs.

Q: Where are EN19 Alloy Steel Forged Die Blocks sourced from in India?

A: These die blocks are available through a vast network of dealers, distributors, exporters, importers, manufacturers, and retailers throughout India, allowing for extensive regional availability and reliable supply chains.

Q: What is the process for verifying the grade and quality of EN19 Forged Die Blocks?

A: Each block is stamped with its grade for traceability and quality assurance. Additionally, the supplier's documentation will specify delivery conditions, microstructure, machinability, and enhanced crack resistance.

Q: Can these die blocks be polished to a high finish for precision tools?

A: Yes, EN19 Forged Die Blocks possess excellent polishing capability, making them suitable for applications demanding superior surface finishes, such as molds and high-precision tooling.