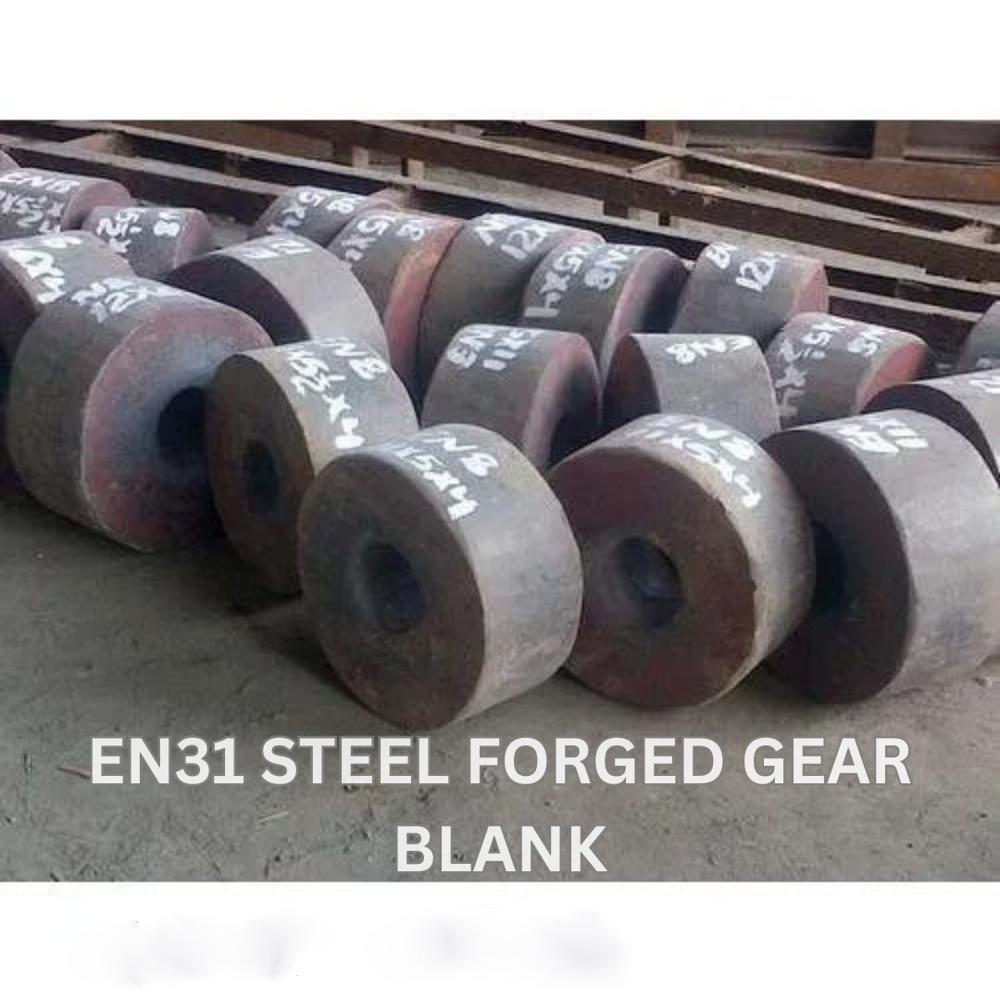

About En31 Alloy Steel Forged Gear Blank

Steel World is stockiest, supplier,dealer and manufacturer of the En31 Steel Forged Gear Blank . EN31 Steel, also known as 535A99 steel, is a high-carbon alloy steel commonly supplied in the spheroidized annealed condition. After machining, it is subsequently hardened and lightly tempered to achieve a high surface hardness. Here are the key details for EN31 Forged Round Bars:Composition:Carbon : 0.90 - 1.20%Manganese (Mn): 0.30 - 0.75%Silicon (Si): 0.10 - 0.35%Chromium (Cr): 1.00 - 1.60%Phosphorus (max): 0.050%Sulfur (max): 0.050%Heat Treatment:Forging: Heat slowly to 1000-1050C and begin forging. Allow sufficient time at the forging temperature for thorough soaking. Reheat as necessary and avoid forging below 850C.Cooling: Cool slowly, preferably in a furnace.EN31 Forged Round Bars find applications in various components, including ball and roller bearings, bearing rings, connecting rods, lathe centers, and morePrecision Engineering for Demanding ApplicationsOur En31 Alloy Steel Forged Gear Blanks are developed to meet the stringent requirements of various industries, ensuring high strength and extended service life. The fine-grained martensite microstructure and as-forged or rough-machined options offer flexibility and performance, making them ideal for use in gears operating under high stress and wear conditions.

Tailored Solutions and Flexible Supply ChainWe provide made-to-order gear blanks, allowing customers to specify dimensions and heat treatment as needed. As a leading dealer, distributor, exporter, and supplier in India, we guarantee the availability and timely delivery of high-quality En31 gear blanks through a robust supply chain network for both small and bulk orders.

FAQ's of En31 Alloy Steel Forged Gear Blank:

Q: How is the En31 Alloy Steel Forged Gear Blank manufactured?

A: The En31 forged gear blank is produced using specialized forging techniques that enhance its grain structure, followed by machining to achieve rough or as-forged finishes. The process ensures excellent forgeability and maintains a fine-grained martensite microstructure for superior properties.

Q: What are the advantages of choosing this gear blank for industrial applications?

A: En31 Alloy Steel Forged Gear Blanks offer high wear resistance, superior impact strength, and good machinability, making them ideal for use in heavy-duty machinery, automotive transmissions, and other applications subjected to intensive wear and stress.

Q: When should heat treatment be applied to these gear blanks?

A: Heat treatment is recommended when additional mechanical properties, such as enhanced hardness or toughness, are required for specific applications. Heat treatment can be performed on request, based on the intended use and performance criteria.

Q: Where are these gear blanks commonly used?

A: These blanks are widely utilized in the manufacture of gears for automotive, industrial machinery, mining equipment, and other sectors where high durability and impact resistance are essential.

Q: What is the process for ordering and customization?

A: En31 gear blanks are made to order, allowing customers to specify dimensions, tolerances, and any special heat treatment required. Orders can be placed through our distribution network across India, ensuring tailored solutions that meet individual project needs.

Q: How does the fine-grained martensite microstructure benefit users?

A: A fine-grained martensitic structure imparts higher toughness, superior wear resistance, and consistent performance, ensuring longevity and reliability in demanding operational environments.